Approval in Principle (AiP)

In recent years, the maritime industry has been developing and implementing various new technologies in response to environmental regulations, digitalization, and technological innovations in related areas. On the other hand, in the implementation of technologies with novel concepts, as the installation of technologies on ships needs to be ensured to have the level of safety equivalent to those required by international conventions and classification rules, the Society inspects technologies to confirm their safety from such point of view.

Design inspections of the Society are usually carried out at the stage in which the product design of the new technology has been completed. However, if a critical issue from the viewpoint of international conventions and classification rules is found at the stage of design completion, it may cause backward progress in the design, which in turn may greatly impede the speed of product development. In order to prevent such situations, the Society provides a service for checking the design of a product in its early design stage or before a specific ship that will implement the product is determined, prior to the final ship classification design review.

What is AiP?

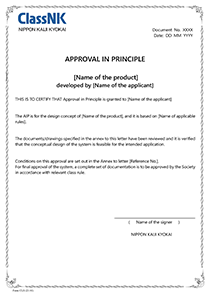

AiP, which stands for Approval in Principle, is a scheme for the examination of plans and documents based on the rules for products in the early design stage to confirm their technical feasibility from the viewpoint of the rules.

The AiP is generally applied to technologies that are newly developed or have little experince in the maritime industry. The product concepts, including but not limited to the following examples, may be subject to an AiP.

Examples of ships

- Ships using alternative fuels (LNG, LPG, methanol, ammonia, hydrogen, etc.)

- Ships carrying special liquefied gases (liquefied hydrogen, liquefied CO2, etc.)

- Automated/autonomous ships

- Offshore floating facilities (FPSO, FLNG, FSRU, offshore plants, etc.)

Examples of equipment and systems

- Liquefied gas cargo/fuel containment systems

- Wind assisted propulsion systems

- Fuel supply systems

- Gas reforming systems

Under the scheme, the applicant submits the design documents at approximately the basic design level to the Society, and the Society reviews them based on the framework agreed upon with the applicant and issues an AiP Certificate for the product whose feasibility is confirmed.

As an AiP is focused on "feasibility" in the initial design stage, it does not directly lead to the final plan approval. Through this stage, the applicant can identify issues based on the philosophy of the rules and regulations in the early stages, and can clarify the key points of the design that need to be cleared in order to obtain the final approval of the drawings. Therefore, it is a practical scheme for efficiently performing design work to achieve final plan approval.

Approval Framework

As the AiP does not certify complete conformity to rules, its framework is decided upon consultation with reference to the provisions of relevant rules, taking into consideration the design stage of the concerned product and the applicant's requirements. The framework for the AiP is generally determined by the following procedure.

- (1) Confirmation of the product specifications

- (2) Determination of referenced rules

- (3) Determination of the scope of approval

Required Documents

The documents that need to be checked in the AiP scheme are determined according to the approval framework agreed upon with the applicant. The required documents will vary according to the details of the agreement, but in general, they should include the following.

- (1) Documents pertaining to product specifications

- (2) Documents pertaining to technical validation of the product

- (3) Documents pertaining to risk assessment

For reference, specific examples of the documents required for the AiP are shown below, using several products as examples.

Table 1 Examples of basic design approval documents for alternative fuelled ships

| 1 | Basic specifications for the vessel |

|---|---|

| 2 | Basic specifications for alternative fuel related equipment |

| 3 | General arrangement drawings |

| 4 | Engine room layout diagram |

| 5 | Alternative fuel piping system diagram |

| 6 | Hazardous location identification diagram |

| 7 | Ventilation system diagram |

| 8 | Fire extinguishing and fire protection system diagram |

| 9 | Longitudinal strength and non-damage restoration calculations |

| 10 | Documents relating to risk assessment |

Table 2 Examples of basic design approval documents for battery propelled ships

| 1 | Basic specifications for ship |

|---|---|

| 2 | Basic specifications for battery equipment |

| 3 | Basic specifications for energy management system |

| 4 | General arrangement drawings |

| 5 | Engine room layout drawings |

| 6 | Battery room layout diagram |

| 7 | Power system diagram |

| 8 | Hazardous location identification diagram |

| 9 | Fire extinguishing and fire protection equipment diagram |

| 10 | Longitudinal strength and non-damage restoration calculations |

| 11 | Documents for risk assessment |

Table 3 Examples of basic design approval documents for offshore floating facilities

| 1 | Basic specifications for floating facilities |

|---|---|

| 2 | General arrangement drawing |

| 3 | Central cross-sectional drawing |

| 4 | Structural analysis method for hull and mooring equipment |

| 5 | Longitudinal strength and non-damage restoration calculations |

| 6 | Basic design clauses for topside equipment |

| 7 | Equipment list for topside facilities |

| 8 | Process flow diagram for topside equipment |

| 9 | Hazardous location identification diagram |

| 10 | Fire fighting and fire protection equipment diagram |

| 11 | Normal and emergency operating concept |

| 12 | Documents for risk assessment |

Table 4 Examples of basic design approval documents for wind propulsion equipment

| 1 | Basic specifications of the equipment |

|---|---|

| 2 | Overall assembly drawing |

| 3 | Detailed structural drawing |

| 4 | Structural analysis method (including trial analysis results for typical loading conditions) |

| 5 | Drive unit structural drawing |

| 6 | Power system diagram |

| 7 | Normal and emergency operating concept |

| 8 | Material for risk assessment (including discussion of effects on the vessel) |

For other details on the AiP scheme, see Guidelines for Basic Design Approval and General Design Approval (Edition 1.0). The Guidelines can be downloaded from “ClassNK MyPage” after the registration.

ClassNK MyPage Login > Guidelines

Trends of AiP and approval records

LNG/LPG/methanol fuelled ships

For alternative fuels, such as LNG/LPG/methanol fuels, where the ships fuelled with them have already been in service, the development from basic design to detailed design has progressed relatively smoothly, and design approval is often granted without going through the stage of obtaining an AiP as an implementation project. For methanol fuels, designs are planned not only for methanol carriers using methanol cargo as fuel but also for methanol fuelled bulk carriers and container ships.

Ammonia-fuelled ship

In parallel with the ongoing development of ammonia-fuelled engines, systems for supplying ammonia fuel to engines and the design of ships equipped with these engines and systems are underway. Ammonia is highly toxic and corrosive, so in order to confirm the feasibility from the initial design stage, an AiP is issued based on the Society's Guidelines for Alternative Fuelled Ships (methanol/ethanol/LPG/ammonia) after checking safe handling on board and identifying issues to be considered in the detailed design. We also issue AiP for 'Ammonia Fuel Ready' for ships using conventional fuels, in which a conceptual design is prepared in advance in anticipation of future conversion to ammonia fuels for zero-emission ships.

Hydrogen-fuelled ships and fuel-cell-powered ships

The use of hydrogen fuel has already been realized in small coastal vessels equipped with fuel cells. Hydrogen-fuelled engines are also being developed for the future use of decarbonized fuels in larger ships. Due to the physical properties of hydrogen, safety measures are required, particularly against hydrogen embrittlement of materials, leakage, and fire. In addition, when hydrogen is liquefied for use on board to store large quantities of fuel, safety measures are also required to ensure the resistance of materials to cryogenic temperatures of -253°C and to the liquefaction of the surrounding air (nitrogen, oxygen, etc.). As the development of hydrogen-fuelled engines progresses, applications of AiP certification are expected to increase in order to confirm the feasibility of ships equipped with hydrogen-fuelled engines.

CO2 carriers and Carbon Capture

Projects for marine transportation of CO2 captured from onshore power plants and other sources are gaining momentum, and the number of AiPs issued for liquefied CO2 carriers is increasing accordingly. A system has also been developed to capture CO2 emitted from ships on board, based on land-based CO2 capture technology. In the future, we expect to see an increase in the application of AiP to confirm the feasibility of ships equipped with liquefaction and storage systems on board, in addition to the CO2 capture system.

Wind-assisted propulsion ship

As one of the technologies for reducing GHG emissions, devices have been developed and are already being put into practical use to assist ship propulsion by utilizing the power of wind, a renewable energy source. Rigid sails, kites, rotor sails, and other systems have been developed for these wind-assisted propulsion systems, and AiPs have been issued for ships equipped with these systems on deck after confirming their feasibility based on the Society's 'Guidelines for Wind-assisted Propulsion Systems for Ships.' Ships combining the use of the above-mentioned alternative fuels with wind-assisted propulsion systems are also being planned.

The table below shows the AiP results published to date.

(As of 1 December 2025)

| No. | Applicant Subject Link |

Date of publication |

|---|---|---|

| 1 | Namura Shipbuilding Co., Ltd. | 6 March 2013 |

| Minimal Ballast Water VLCC Design | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=94&type=p&layout=5 | ||

| 2 | Mitsubishi Heavy Industries, Chiyoda Corporation | 12 November 2014 |

| H2/CO2 FPSO | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=1151&type=p&layout=9 | ||

| 3 | Maritime Innovation Japan Corporation (MIJAC). | 17 November 2015 |

| LNG-fueled bulk carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=1721&type=p&layout=1 | ||

| 4 | Hanjin Heavy Industries & Construction Co., Ltd. | 20 October, 2016 |

| LNG Bunkering Vessel | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=2134&type=p&layout=5 | ||

| 5 | Nippon Yusen Kabushiki Kaisha, Japan Marine United | 5 July 2018 |

| LNG-fuelled 200K DWT bulk carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=2961&type=p&layout=1 | ||

| 6 | Kawasaki Heavy Industries | 31 January 2019 |

| LNG-fuelled 207K DWT bulk carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=3544&type=p&layout=1 | ||

| 7 | Osaka Gas, Daihatsu Diesel | 24 September 2019 |

| LPG Reformer for marine engines | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=4162&type=p&layout=1 | ||

| 8 | Mitsui O.S.K. Lines, Ltd.,Oshima Shipbuilding Co.,Ltd. | 3 October 2019 |

| Wind Challenger Project | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=4202&type=p&layout=1 | ||

| 9 | NS United Kaiun Kaisha, Ltd.,Imabari Shipbuilding Co., Ltd. | 17 December 2019 |

| LNG-fueled capesize bulker | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=4442&type=p&layout=5 | ||

| 10 | Kawasaki Heavy Industries, Ltd. | 5 February 2020 |

| LPG Fuel Supply System | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=4602&type=p&layout=1 | ||

| 11 | Daihatsu Diesel, Iino Gas Transport, Osaka Gas, Izumi Steel Works, Miura Shipbuilding | 13 March 2020 |

| LPG reformed gas fueled coastal LPG carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=4803&type=p&layout=5 | ||

| 12 | SHIN KURUSHIMA DOCKYARD CO., LTD | 1 April 2020 |

| LNG-fueled chemical tanker | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=4864&type=p&layout=5 | ||

| 13 | Imabari Shipbuilding Co., Ltd.,Mitsubishi Shipbuilding Co., Ltd | 27 April 2020 |

| 180,000 DWT LPG dual fuelled bulk carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=4925&type=p&layout=5 | ||

| 14 | Nippon Yusen Kabushiki Kaisha,MTI Co., Ltd. | 14 May 2020 |

| autonomous ship framework (development code “APExS”) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=4983&type=p&layout=1 | ||

| 15 | Kawasaki Kisen Kaisha, Ltd., AIRSEAS SAS | 19 August 2020 |

| Automated kite system “Seawing”. | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=5242&type=p&layout=1 | ||

| 16 | Sumitomo Heavy Industries Marine & Engineering Co., Ltd. | 22 March 2021 |

| Methanol dual-fueled tanker | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=5945&type=p&layout=1 | ||

| 17 | Kawasaki Heavy Industries, Ltd. | 7 May 2021 |

| Cargo Containment System for Large Liquefied Hydrogen Carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=6124&type=p&layout=1 | ||

| 18 | Eco Marine Power | 26 May 2021 |

| Renewable energy system for ships, “Aquarius Marine Renewable Energy with EnergySail” | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=6203&type=p&layout=1 | ||

| 19 | TSUNEISHI SHIPBUILDING Co., Ltd. | 16 June 2021 |

| LNG-fueled bulker “KAMSARMAX GF” | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=6265&type=p&layout=1 | ||

| 20 | Kawasaki Kisen Kaisha, Ltd., Shin Kurushima Dockyard Co. Ltd. | 8 December 2021 |

| Ammonia-fuelled PCC | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=7022&type=p&layout=1 | ||

| 21 | Planning and Design Center for Greener Ships (GSC) | 20 January 2022 |

| Ammonia-fueled Panamax bulk carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=7262&type=p&layout=1 | ||

| 22 | Nippon Yusen Kabushiki Kaisha, MTI Co., Ltd., Japan Marine Science Inc. | 15 March 2022 |

| Fully autonomous ship framework (development code “APExS-auto”) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=7482&type=p&layout=1 | ||

| 23 | Hitachi Zosen Corporation, Mitsui O.S.K. Lines, Ltd., Yanmar Power Technology Co., Ltd. | 16 March 2022 |

| Methane Oxidation Catalyst System | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=7502&type=p&layout=1 | ||

| 24 | GTT’ | 31 March 2022 |

| LNG fuel tank with 2 bar gauge design pressure | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=7662&type=p&layout=1 | ||

| 25 | Japan Offshore Design & Engineering Platform Technology & Engineering Research Association (J-DeEP). | 4 April 2022 |

| Floating offshore hydrogen production plant | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=7682&type=p&layout=1 | ||

| 26 | Planning and Design Center for Greener Ships (GSC) | 21 April 2022 |

| Ammonia-ready LNG-fueled Panamax Bulk Carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=7862&type=p&layout=1 | ||

| 27 | Kawasaki Heavy Industries, Ltd. | 28 April 2022 |

| Large Liquefied Hydrogen Carrier "Following AiPs for CCS, CHS, and Dual-fuel Main Boilers" | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=7923&type=p&layout=1 | ||

| 28 | Mitsubishi Shipbuilding Co., Ltd., Nippon Yusen Kabushiki Kaisha | 16 May 2022 |

| Large Liquefied CO2 (LCO2) Carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=8002&type=p&layout=1 | ||

| 29 | Mitsubishi Shipbuilding Co.,Ltd | 9 June 2022 |

| Ammonia-ready VLGC | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=8082&type=p&layout=1 | ||

| 30 | Nippon Yusen Kabushiki Kaisha,IHI Power Systems Co., Ltd. | 12 July 2022 |

| Ammonia-fueled tugboat (A-Tug) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=8262&type=p&layout=1 | ||

| 31 | Mitsui O.S.K. Lines, Ltd. | 23 August 2022 |

| Large-scale Liquefied CO2 (LCO2) Carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=8462&type=p&layout=1 | ||

| 32 | Nippon Yusen Kabushiki Kaisha, Japan Engine Corporation, IHI Power Systems Co., Ltd., Nihon Shipyard Co., Ltd. | 7 September 2022 |

| Ammonia-fueled ammonia gas carrier (AFAGC) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=8542&type=p&layout=1 | ||

| 33 | Nippon Yusen Kabushiki Kaisha | 28 September 2022 |

| Ammonia Bunkering Vessel (ABV) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=8682&type=p&layout=1 | ||

| 34 | ITOCHU Corporation, Nihon Shipyard Co.,Ltd., Mitsui E&S Machinery Co., Ltd., Kawasaki Kisen Kaisha, Ltd., NS United Kaiun Kaisha, Ltd. | 28 November 2022 |

| Ammonia fueled 200,000 DWT type bulk carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=8962&type=p&layout=1 | ||

| 35 | Kawasaki Heavy Industries, Ltd | 30 November 2022 |

| Dual fuel generator engine using hydrogen gas as fuel and related machinery systems & arrangements for 160,000m3 Liquefied Hydrogen Carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=8983&type=p&layout=1 | ||

| 36 | Nippon Yusen Kabushiki Kaisha, Nihon Shipyard Co., Ltd., IHI Corporation | 5 January 2023 |

| Ammonia Floating Storage and Regasification Barge (A-FSRB) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=9102&lang=EN&layout=1 | ||

| 37 | Mitsui O.S.K. Lines, Ltd.,MITSUI & CO., LTD | 27 January 2023 |

| large ammonia fueled 210,000 DWT bulk carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=9202&type=p&layout=1 | ||

| 38 | GTT | 7 March 2023 |

|

- Concept of 12,500m3 LNG Dual-fuelled VLCC fitted with Mark III Flex system - Concept of LNG Fuel Tanks with NH3 ready notation that includes material compatibility with NH3, risk assessment and Boil-off gas management - Concept of 8,000 CEU PCTC LNG Dual-fuelled with NH3 ready notation - Recycool™ system applied to LNG fuelled vessels which is designed for allowing the reliquefaction of LNG evaporation in order to reduce greenhouse gas emissions and economic losses |

||

| https://www.classnk.or.jp/hp/en/news.aspx?id=9402&type=p&layout=5 | ||

| 39 | TOA Corporation,NIHON SHIPYARD CO.,LTD.,Japan Marine United Corporation | 14 April 2023 |

| Conversion plan of the medium-sized self-elevating platform (SEP) vessel | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=9622&type=p&layout=1 | ||

| 40 | Mitsui O.S.K. Lines, Ltd.,TSUNEISHI SHIPBUILDING Co., Ltd.,Mitsui E&S Shipbuilding Co., Ltd. | 14 April 2023 |

| Ammonia Fuelled Gas Carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=9644&type=p&layout=1 | ||

| 41 | Mitsubishi Shipbuilding Co., Ltd.Nippon Yusen Kabushiki Kaisha | 29 June 2023 |

| Ammonia and Liquefied CO2 Carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=9982&type=p&layout=1 | ||

| 42 | GTT | 25 July 2023 |

| Cargo Containment System (CCS) and Cargo Handling System (CHS) for liquefied hydrogen carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10082&type=p&layout=1 | ||

| 43 | Samsung Heavy Industries (SHI) | 14 August 2023 |

| Ammonia fuel supply system for oil tanker and container ship | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10142&type=p&layout=1 | ||

| 44 | China Shipbuilding Power Engineering Institute Co., Ltd. (CSPI), a member of CSSC Power (Group) Co. Ltd. (CPGC) | 7 September 2023 |

| Onboard CO2 capture and storage (OCCS) system | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10222&type=p&layout=1 | ||

| 45 | Mitsui O.S.K. Lines, Ltd., MOL Drybulk Ltd., Onomichi Dockyard Co., Ltd., Kawasaki Heavy Industries, Ltd., Japan Engine Corporation | 19 October 2023 |

| Parcel layout concept for hydrogen-fueled multi-purpose vessel | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10422&type=p&layout=1 | ||

| 46 | Shanghai Merchant Ship Design & Research Institute (SDARI) | 6 December 2023 |

|

- Ammonia ready LNG dual fueled 7,000CEU vehicle carrier - Ammonia dual fueled 10,000CEU vehicle carriers - Methanol dual fueled 10,000CEU vehicle carriers |

||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10562&type=p&layout=1 | ||

| 47 | Marine Design & Research Institute of China (MARIC) | 7 December 2023 |

|

- 210k methanol dual-fueled bulk carrier - 210k ammonia dual-fueled bulk carrier - 210k LNG dual-fueled bulk carrier - 88k LPG dual-fueled very large gas carrier |

||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10582&type=p&layout=1 | ||

| 48 | Kawasaki Kisen Kaisha, Ltd., Kawasaki Kinkai Kisen Kaisha, Ltd., Japan Radio Co., Ltd., YDK Technologies Co., Ltd. | 12 December 2023 |

| Advanced Maneuvering Assistant System | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10602&type=p&layout=1 | ||

| 49 | Mitsui O.S.K. Lines, Ltd., Mitsubishi Shipbuilding Co., Ltd. | 22 December 2023 |

| Ammonia FSRU (Ammonia Floating Storage and Regasification Unit) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10682&type=p&layout=1 | ||

| 50 | YANMAR Power Technology Co., Ltd. | 17 January 2024 |

| Maritime hydrogen fuel cell system | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10742&type=p&layout=1 | ||

| 51 | Planning and Design Center for Greener Ships (GSC) | 6 February 2024 |

| Prismatic ammonia fuel tank (IMO Type B independent tank) for container ships | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10882&type=p&layout=1 | ||

| 52 | “K” Line Wind Service, Ltd., Japan Marine United Corporation, Nihon Shipyard Co., Ltd. | 28 February 2024 |

| Multi-functional floating offshore windfarm support vessel (MFSV) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?id=10982&type=p&layout=1 | ||

| 53 | Mitsui E&S Shipbuilding Co., Ltd. | 11 April 2024 |

| Methanol fuel supply system | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=11305&layout=1 | ||

| 54 | Mitsubishi Shipbuilding Co., Ltd. | 11 April 2024 |

| Ammonia fuel supply system and ammonia gas abatement system | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=11303&layout=1 | ||

| 55 | Hitachi Zosen Corporation, Mitsui O.S.K. Lines, Ltd. (MOL) , Yanmar Power Technology Co., Ltd. (Yanmar PT) | 11 April 2024 |

| Methane slip reduction system | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=11302&layout=1 | ||

| 56 | UYENO TRANSTECH LTD., YANMAR POWER TECHNOLOGY CO., LTD., Mitsui E&S Shipbuilding Co., Ltd. | 2 July 2024 |

| Hydrogen-fueled engine compatible 5,000KL oil tanker | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=11624&layout=1 | ||

| 57 | Nippon Yusen Kabushiki Kaisha (NYK Line) ,TB Global Technologies Ltd. | 31 July 2024 |

| Ammonia fuel bunkering boom | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=11842&layout=1 | ||

| 58 | Mitsui O.S.K. Lines, Ltd. ,Hanwha Ocean Co., Ltd. | 2 August 2024 |

| LNG carrier equipped with a Wind-Assisted Propulsion System (WAPS) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=11882&layout=1 | ||

| 59 | Kawasaki Kisen Kaisha, Ltd., Mitsui O.S.K. Lines, Ltd., Nihon Shipyard Co., Ltd., Nippon Yusen Kabushiki Kaisha, Mitsui & Co., Ltd., Mitsubishi Corporation, and Mitsubishi Shipbuilding Co., Ltd. | 18 September 2024 |

| Large liquefied CO2 carriers of 50,000 m³ and 23,000 m³ | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=12242&layout=1 | ||

| 60 | GTT | 29 October 2024 |

| 30,000 m³ LNG carrier equipped with two Mark III Flex membrane tanks | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=12482&layout=1 | ||

| 61 | Samsung Heavy Industries Co., Ltd. | 30 October 2024 |

| Autonomous Navigation Assistance System “SAS” | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=12502&layout=1 | ||

| 62 | Mitsubishi Shipbuilding Co., Ltd. and Nippon Gas Line Co., Ltd. | 5 February 2025 |

| Coastal liquefied CO2 carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=12982&layout=1 | ||

| 63 | Nippon Yusen Kabushiki Kaisha (NYK Line) ,LMG Marin AS(a member of the Seatrium Group). | 26 February 2025 |

| Ammonia-fuelled Ammonia bunkering vessel | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=13062&layout=1 | ||

| 64 | Mitsui O.S.K. Lines, Ltd., Namura Shipbuilding Co., Ltd., Mitsubishi Shipbuilding Co., Ltd. | 17 March 2025 |

| Large-size ammonia-powered ammonia carrier | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=13183&layout=1 | ||

| 65 | OceanWings | 27 March 2025 |

| Rigid Windsail Type Wind-Assisted Propulsion System (WAPS) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=13284&layout=1 | ||

| 66 | Knutsen NYK Carbon Carriers AS ("KNCC"), a subsidiary of Nippon Yusen Kabushiki Kaisha ("NYK") ,Knutsen Group, | 27 March 2025 |

| Liquified CO2 carriers ("LCO2-EP carrier") that use the elevated pressure (EP) method to store and transport liquefied carbon dioxide (LCO2) at ambient temperature | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=13283&layout=1 | ||

| 67 | TSUNEISHI SHIPBUILDING Co., Ltd. , Fonden Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping | 4 April 2025 |

| Retrofitted Kamsarmax bulk carrier, converting it from conventional fuel to methanol dual-fuel | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=13363&layout=1 | ||

| 68 | Mitsubishi Shipbuilding | 27 March 2025 |

| Onboard Carbon Capture and Storage system (OCCS) | ||

| https://www.classnk.or.jp/hp/en/news.aspx?type=p&id=13422&layout=1 | ||

| 69 | Mitsubishi Shipbuilding Co., Ltd. , Mitsui O.S.K. Lines, Ltd. | 30 June 2025 |

| LCO2/Methanol Carrier | ||

| https://www.classnk.or.jp/hp/en/hp_pressrelease.aspx?id=13762&layout=1 | ||

| 70 | Kawasaki Heavy Industries, Ltd. , MITSUI E&S Co., Ltd. | 8 September 2025 |

| ammonia fuelled LPG/NH₃ carrier | ||

| https://www.classnk.or.jp/hp/en/hp_pressrelease.aspx?id=13982&layout=1 | ||

| 71 | Dalian Shipbuilding Offshore Co., Ltd. (DSOC) , Nantong Offshore Design & Research Institute Co. Ltd (NODRI) . | 12 September 2025 |

| large liquefied CO2 carrier (50,000m3) | ||

| https://www.classnk.or.jp/hp/en/hp_pressrelease.aspx?id=14022&layout=1 | ||

| 72 | SRC Group. | 1 October 2025 |

| methanol fuel tank design concept | ||

| https://www.classnk.or.jp/hp/en/hp_pressrelease.aspx?id=14062&layout=1 | ||

| 73 | Samsung Heavy Industries Co., Ltd. | 22 October 2025 |

| “Samsung Remote Operation Center (SROC)”, a shore-based remote monitoring system | ||

| https://www.classnk.or.jp/hp/en/hp_pressrelease.aspx?id=14182&layout=1 | ||

| 74 | Kawasaki Heavy Industries, Ltd. | 14 November 2025 |

| Safety Berthing/Unberthing Assistance System | ||

| https://www.classnk.or.jp/hp/en/hp_pressrelease.aspx?id=14322&layout=1 | ||

For applications and service enquiries

Tel: +81-3-5226-2042

Fax: +81-3-5226-2736

E-Mail: tsd@classnk.or.jp