Ship Recycling Convention (the Hong Kong Convention)

What is the Ship Recycling Convention?

The Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, 2009 (the Ship Recycling Convention or the Hong Kong Convention) was adopted in May 2009. After the entry into force of the Convention, the development and maintenance of an Inventory of Hazardous Materials, which identifies the amount and location of hazardous materials onboard a ship, will be required for all ships over 500GT. Furthermore, ships shall only be recycled at ship recycling facilities authorized by the competent authority. The following conditions have been met and the Convention will therefore enter into force on 26 June 2025.

1. Ratification by 15 States,

2. Representation by 40 per cent of world merchant shipping by gross tonnage, and

3. A maximum annual ship recycling volume not less than 3 per cent of the combined tonnage of the ratifying States

As of June 2023, the following twenty-two (22) countries have ratified.

Bangladesh, Belgium, Congo, Croatia, Denmark, Estonia, France, Germany, Ghana, India, Japan, Liberia, Luxembourg, Malta, Netherlands, Norway, Panama, Portugal, Sao Tome and Principe, Serbia, Spain, and Türkiye have acceded to the Convention.

Regulation (EU) No 1257/2013 on Ship Recycling (EU-SRR)

Regulation (EU) No. 1257/2013 on Ship Recycling (EU-SRR), which is aimed at facilitating early ratification of the Hong Kong Convention 2009 - both within the EU and in other countries outside the EU - by applying controls to ships and ship recycling facilities on the basis of the Hong Kong Convention, came into effect in December 2013 and requirements such as the development of the inventory of hazardous materials (IHM) are applied from December 31, 2018 to EU flagged new ships and from December 31 2020 to EU flagged existing ships and Non-EU flagged ships calling at a port or anchorage of an EU member state.

For the IHM, New and Existing EU flagged ships must comply with Article 5 of the EU SRR, and Non-EU flagged ships must comply with its Article 12.

For Non-EU flagged ships, a statement of compliance (SOC) shall be issued in accordance with Article 12.6 of the EU-SRR after verification of the IHM by the relevant authorities of a Non-EU country whose flag the ship is flying or an organization authorized by them, in accordance with the national requirements. These documents shall be issued by or on behalf of the Flag state.

Considering that several thousand ships are likely to be unable to comply with the IHM obligations and may not have the required certification by the deadline of 31 December 2020 due to the disruptions caused by COVID-19, European Commission has published: Commission Notice 2020/C 349/01, suggesting EU member States to apply a harmonized approach towards enforcement during ship inspections, for a limited period of 6 months that is from 31 December 2020 to 30 June 2021.

Please refer to the following technical information for more details.

- 2023/12/20 TEC-1313

Compliance with the Ship Recycling Convention / Regulation (EU) No. 1257/2013 on Ship Recycling (EU-SRR)- For Liberian flagged vessels - 2023/10/30 TEC-1311

The Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, 2009 (the Ship Recycling Convention) - 2022/11/8 TEC-1278

“Compliance with the EU Ship Recycling Regulation - For Panamanian flagged vessels” - 2022/1/21 TEC-1255

"IHM Certificate to Part I of the Inventory of Hazardous Materials" and "EU Regulation on Ship Recycling" for Japanese flagged ships - 2020/9/3 TEC-1207

“Compliance with the EU Ship Recycling Regulation - Non-EU flagged vessels” - 2019/7/1 TEC-1185

“Adding Note on Survey Status to EU flagged ships which are subject to EU Regulation on Ship Recycling” - 2018/12/28 TEC-1170

“Commencement of the EU Regulation on Ship Recycling” - 2014/1/15 TEC-0978

“Introduction to the EU Regulation on Ship Recycling”

ClassNK may issue the Statement of Compliance (SOC) to the Hong Kong Convention and/the EU-SRR (Article 5 for EU flagged ships and Article 12 for non-EU flagged ships), in accordance with the authorization and instruction from each flag administration.

The status of authorization delegated to ClassNK is as follows.

- This information is subject to change according to the instruction of each flag state.

- Please ask for the status of a flag state that is not listed in the website, as in such cases the authorization may be given on a ship by ship basis.

○: ClassNK is authorized to issue “Statement of Compliance (SOC)” or “EU Inventory Certificate (EU Certificate)” for Inventory of Hazardous Materials on behalf of the Administration.

| Flag administration | SOC to the Hong Kong Convention (Ship Recycling Convention) | Cert or SOC to the EU Ship Recycling Regulation (EU-SRR) | Intl’ Cert on IHM | Remarks |

|---|---|---|---|---|

| Antigua and Barbuda | O | |||

| Bahamas | O | O | ||

| Bahrain | O | |||

| Barbados | O | O | ||

| Belgium (EU) | O | |||

| Belize | O | O | ||

| British Virgin | O | O |

|

|

| Brunei | O |

|

||

| Cayman Islands | O | O | ||

| Cook Islands | O | O | ||

| Curacao |

|

|||

| Cyprus (EU) | O | |||

| Denmark (EU) | O | |||

| Dominica | O | |||

| Finland (EU) | O | |||

| Georgia | O | |||

| Germany (EU) | O | |||

| Gibraltar | O | O |

|

|

| Greece (EU) | O | |||

| Hong Kong |

|

|||

| India | O |

|

||

| Ireland (EU) | O | |||

| Isle of Man | O | O | ||

| Japan | ||||

| Kiribati | O | O | ||

| Kuwait | O | O | ||

| Lebanon | O |

|

||

| Liberia | O |

|

||

| Libya | O | O | ||

| Lithuania (EU) | O | |||

| Luxembourg (EU) | O | O | ||

| Malaysia | O |

|

||

| Malta (EU) | O | O |

|

|

| Marshall Islands | O | O | ||

| Mauritius | O | O | ||

| Netherlands (EU) | O | |||

| Norway (EU) | O | |||

| Pakistan | O | O | ||

| Palau | O | O | ||

| Panama | O |

|

||

| Philippines | O | O | ||

| Portugal (EU) | O | |||

| San Marino | O | O | ||

| Singapore |

|

|||

| South Africa | O | O | ||

| Sri Lanka | O | |||

| St. Kitts and Nevis | O | O | ||

| St. Vincent and the Grenadines | O | O | ||

| Switzerland | O | O | ||

| Thailand | O | O | ||

| Türkiye | O | |||

| Tuvalu | O | O | ||

| U.K. | O | O |

|

|

| U. S. A. | O | |||

| Vanuatu | O | O | ||

| Vietnam | O |

|

What is the Inventory of Hazardous Materials?

The Inventory of Hazardous Materials (IHM) is a list of hazardous materials, waste and stores in a ship. It identifies their location and approximate quantities onboard the ship. As shown in the table below, Part I of the IHM is developed at the design and construction stage, and Part II and Part III are developed before a ship is recycled. However, Part I of the IHM for existing ships, whose building contracts have been placed before the entry into force of the Convention, is developed not later than 5 years after the entry into force of the Convention. The information provided by the IHM is utilized by ship recycling facilities in order to protect human health and safety and prevent environmental pollution.

Composition of the IHM

| Part I | Part II | Part III | |

|---|---|---|---|

| Materials contained in ship structure or equipment | Operationally generated waste | Stores | |

| Time of Development | At delivery *Existing ships: not later than 5 years after the entry into force | Before recycling | |

| Items to be listed in the IHM | Table A: Prohibited and/or restricted materials (Asbestos, PCBs, Ozon depleting substances, Anti-fouling compounds and systems) Table B: Hazardous materials (Cadmium, Hexavalent Chromium, Lead, Mercury, etc.) *Existing ships: as far as practicable |

Table C: Potentially hazardous items (Garbage, cargo residues, etc.) |

Table C: Potentially hazardous items (Stores) Table D: Regular consumable goods potentially containing Hazardous Materials |

| ClassNK’s Activity for Ship Recycling |

|---|

ClassNK provides the following solutions so that stakeholders can smoothly implement the requirements of the Convention after its entry into force in the development and maintenance of the IHM.

ClassNK Guidelines, etc.

ClassNK issues “Guidelines for the Inventory of Hazardous Materials” corresponding to Ship Recycling Convention and EU regulations in order to clarify the procedure and requirements for issuance of the SOC. The Guidelines can be downloaded from “ClassNK MyPage” after the registration.

ClassNK MyPage Login > Guidelines

Development of the IHM for existing ships and Issuance of Statement of Compliance

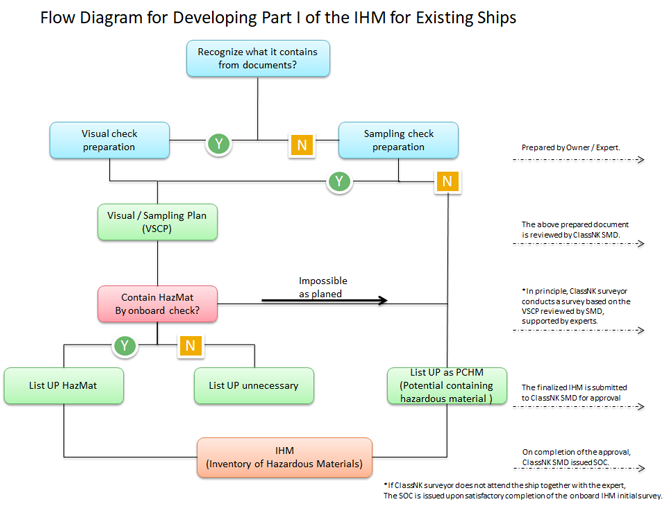

For existing ship, Inventory can be developed by information analysis by Expert, instead of collecting Material Declaration (MD) and Supplier’s Declaration of Conformity (SDoC).“Guidelines for the Inventory of Hazardous Materials”

A Visual Sampling Check Plan (VSCP) shall be submitted at least two weeks prior to the onboard visual sampling date.

Application Form:(English)Application for Confirmation of the

Inventory of Hazardous Materials Loaded on Ships

(Word)

(Japanese)Application for Confirmation of the

Inventory of Hazardous Materials Loaded on Ships

(Word)

E-mail:ihm@classnk.or.jp

In principle, ClassNK surveyor conducts a survey based on the VSCP reviewed by SMD, supported by experts. However the evidence to prove that the visual / sampling check is performed properly is shown in the following manners, the expert may be allowed to visual / sampling check on board by the expert alone.

- At the time of the visual check, it is identified by photos that there is no change in the visual check plan developed by the document analysis (replacement, removal, or new installation of a device different from the device shown in the drawing) and such photos are well organized in investigation result table (checklist) of the IHM. If there is a change in the visual check plan, consider an appropriate investigation method and record the details of the change and the results of the investigation (photos are also attached), i.e., record the survey process for all items and attach photos as evidence.

- At the time of the sampling check, place a sample in a vinyl pouch at the sampling point including the inside of the device, behind the wall. Then take a picture so that the identification number can be identified, and post it on the investigation result table (checklist) of the IHM.

If the ClassNK surveyor does not attend at the same time during the onboard visual / sampling check by experts, after the IHM has been reviewed by HO-SMD, the IHM initial survey will be conducted at the opportunity such as a class periodical survey according to the shipowner's request. The SOC and IHM with approval stamp will be issued upon satisfactory completion of the IHM initial survey. Please note that any doubts regarding the consistency in the IHM and the ship may require further investigation, including sampling by experts.

Supplier’s Material Declaration (SMD) issued by Product Supplier

In the development of Inventory by information analysis, the manufacturer and model of each product are identified by documents such as drawings and visually checked on the ship. If Supplier's Material Declaration (hereinafter referred to as the declaration) by the product supplier is available and it is analyzed that the onboard device matches the contents of the declaration, the IHM may be developed regardless of the sampling check.

Japan Ship Machinery and Equipment Association (JSMEA) (hereinafter referred to as “JSMEA”) confirm that the listed company(in Japanese only) verified that the products do not contain any asbestos in accordance with methods laid down by JSMEA and issue the “Asbestos-Free Sticker” to the listed up products.

listed company (Japan Ship Machinery and Equipment Association (JSMEA))

Development of the IHM for new ships and Issuance of Statement of Compliance

Shipbuilders should develop the IHM for new ships in accordance with the format stipulated in the IMO Guidelines and based on the information obtained from the Material Declaration (MD) and Supplier’s Declaration of Conformity (SDoC) submitted by suppliers. In order to develop the IHM for new ships, shipbuilders and suppliers have to exchange and store a huge number of paper documents. It may be a serious burden for shipbuilders and suppliers. ClassNK developed “PrimeShip-GREEN/SRM” to facilitate IHM development utilizing a Cloud Computing System in cooperation with IBM. After registration to the system via Internet, the people who engaged in the development of the IHM, including shipbuilders and suppliers, are able to perform all necessary work for IHM development on the system website. For registration to “PrimeShip-GREEN/SRM,” please access the following URL, click “Register Organization” on the login page and input the necessary information. “PrimeShip-GREEN / SRM” also supports the development of IHM that meets the requirements of Article 5 of the EU Regulation.

PrimeShip-GREEN/SRM URL: https://www.psgreensrm.com/

【For Shipbuilders】 Ship Recycling Convention and PrimeShip-GREEN/SRM

ClassNK provides following formats and documents. Please download and use them freely.

ClassNK issues Statement of Compliance (SOC) for IHM after conducting review of the IHM developed under the construction at the request from shipbuilders.

Maintenance of IHM and Renewal of Statement of Compliance

Ship owners / ship management companies are required to properly maintain and update IHM Part I throughout the operational life of the ship, reflecting new installations containing Hazardous Materials and relevant changes in ship structure and equipment, considering the IMO Guidelines.

- Appointment of designated person responsible for maintaining and updating of IHM (specified in procedure)

- Establishment of management system for maintaining and updating IHM (with procedure manual)

- Maintaining and updating IHM according to the procedure manual (at the time of every dock, repair, spare parts purchase)

- Identifying equipment and materials to be replaced collection

- Collecting and keeping MD / SDoC

- Updating IHM based on collected MD (signature / revised record of responsible person) - Providing the related documents for the survey or sale of the ship as necessary

An example of the procedure of management system, assuming designation of a responsible person a shore:

An Example of Procedure to Maintain Part I of IHM (PDF)

An Example of Procedure to Maintain Part I of IHM (WORD)

ClassNK renews Statement of Compliance (SOC) for IHM after confirming that IHM is properly maintained and managed at the request from ship owner/manager.

Issuance of Statement of Compliance (SOC) for the IHM

ClassNK issues SOC for Part I of the IHM developed in preparation for the incoming Convention. SOC will be smoothly converted into an International Certificate on Inventory of Hazardous Materials after the entry into force of the Convention. ClassNK recommends the early preparation of the IHM because the need for experts is expected to increase drastically after the entry into force of the Convention.

Issuance of Statement of Compliance (SOC) for Ship Recycling Facilities

After the entry into force of the Convention, ships shall only be recycled at ship recycling facilities authorized in accordance with the Convention. Ship recycling facilities will be required to develop a Ship Recycling Facility Plan (SRFP) to be authorized by the competent authority.

As an independent third-party verification body ClassNK issues a SOC to ship recycling facilities which verifies that they are in compliance with the Hong Kong Convention or other applicable standards, after confirming that the SRFP developed by the ship recycling facilities meet the requirements of the Convention and that the facilities are carrying out recycling procedures in accordance with their SRFP. The scope of the verification includes prevention of adverse effects to human health and the environment, safe and environmentally sound management of hazardous materials, emergency preparedness and response, worker safety and training, reporting on incidents/accidents/occupational diseases/chronic effects, initial notification and reporting, and ship recycling plan. ClassNK verification frameworks consist of an Initial Audit by the on-site inspections carried out during the actual ship recycling process at the facility as well as thorough reviews of its document and management procedures, and Periodical Audits to verify that the SRFP and related systems are effectively implemented. Any non-conformities found in a Periodical Audit are subject to an Additional Audit and may result in suspension or invalidation of the SOC. ClassNK has so far issued SOCs to the following ship recycling facilities around the globe based on its purely technical verification, and paved the way to extend safe and environmentally sound ship recycling practice in line with the international standard.

List of verified ship recycling facilities by ClassNK (As of Middle of March 2024)

| 1 |  |

Facility name: RL Kalthia Ship Breaking Pvt. Ltd. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 70,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 60m, Draft: Any depth URL: www.kalthiashipbreaking.com Open the SOC*2 |

| 2 |  |

Facility name: Priya Blue Industries Pvt. Ltd. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 120,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 120m, Draft: Any depth URL: http://www.priyablue.com Open the SOC*2 |

| 3 |  |

Facility name: Shree Ram Vessel Scrap Pvt. Ltd. and Shree Ram Shipping Industries Pvt. Ltd. |

| 4 |  |

Facility name: Leela Ship Recycling Pvt. Ltd. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 60,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 80m, Draft: Any depth URL: http://www.leelagreenship.com/ Open the SOC*2 |

| 5 |  |

Facility name: R. K. INDUSTRIES (UNIT-II)LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 150,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 60m X 2, Draft: Any depth URL: http://www.shreeramgroup.in Open the SOC*2 |

| 6 |  |

Facility name: JRD Insustries Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 37,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 51m, Draft: Any depth URL: http://www.jrdindustries.net Open the SOC*2 |

| 7 |  |

Facility name: YSI RECYCLERS LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 55m, Draft: Any depth URL: http://www.luckygroupindia.com/ Open the SOC*2 |

| 8 |  |

Facility name: GGSBY INDUSTRIES PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 83 m, Draft: Any depth Open the SOC*2 |

| 9 |  |

Facility name: ALANG AUTO & GENERAL ENGINEERING COMPANY PRIVATE LIMITED Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 49 m, Draft: Any depth URL: http://alangauto.com/ Open the SOC*2 |

| 10 |  |

Facility name: ASHWIN CORPORATION Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: 350m, Breadth: 30m、Draft: 10m Open the SOC*2 |

| 11 |  |

Facility name: EGE CELIK INDUSTRY AND TRADE CORPORATION Location: Türkiye (Izmir) Estimated annual recycling capacity (LDT*1):45,000LDT Dismantling method: landing method Maximum capacity of ship to be recycled: Length: 350m, Breadth: 50 m, Draft: 9m Open the SOC*2 |

| 12 |  |

Facility name: SHREE RAM GREEN SHIP RECYCLING INDUSTRIES (UNIT II) LLP. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1):45,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: Any length, Breadth: 45 m, Draft: Any depth URL: http://www.shreeramgroup.in/ Open the SOC*2 |

| 13 |  |

Facility name: BAIJNATH MELARAM Location: India (Gujarat) Estimated annual recycling capacity (LDT*1):60,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Length: 400m, Breadth: 80 m, Draft: Any depth URL: http://www.baijnathmelaram.com/ Open the SOC*2 |

| 14 |  |

Facility name: TRIVENI SHIPBREAKERS PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1):30,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 45m, Draft: Any depth Open the SOC*2 |

| 15 |  |

Facility name: LUCKY STEEL INDUSTRIES (S.B.D) Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 80,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 36m, Draft: Any depth URL: http://www.luckygroupindia.com/ Open the SOC*2 |

| 16 |  |

Facility name: LAKSHMI GREEN SHIP RECYCLERS LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 70,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 52m, Draft: Any depth Open the SOC*2 |

| 17 |  |

Facility name: JAWANDAMAL DHANNAMAL Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 25,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 44m, Draft: Any depth Open the SOC*2 |

| 18 |  |

Facility name: BANSAL SHIP BREKAERS Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 80,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 75m, Draft: Any depth Open the SOC*2 |

| 19 |  |

Facility name: PANCHVATI SHIP BREAKERS Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 50,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 60m, Draft: Any depth Open the SOC*2 |

| 20 |  |

Facility name: BANSAL SHIP RECYCLERS LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 60,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 45m, Draft: Any depth URL: http://bansalgroupindia.com/ship-re-cycling/ Open the SOC*2 |

| 21 |  |

Facility name: HOOGHLY SHIPBREAKERS LIMITED Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 100m, Draft: Any depth Open the SOC*2 |

| 22 |  |

Facility name: NBM IRON AND STEEL TRADING PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 50,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 48m, Draft: Any depth Open the SOC*2 |

| 23 |  |

Facility name: SHUBH ARYA STEEL PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 95m, Draft: Any depth Open the SOC*2 |

| 24 |  |

Facility name: LEELA GREEN SHIP RECYCLING PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 60,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 40m, Draft: Any depth URL: http://www.leelagreenship.com/ Open the SOC*2 |

| 25 |  |

Facility name: P. RAJESH SHIP BREAKING PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 47m, Draft: Any depth Open the SOC*2 |

| 26 |  |

Facility name: SACHDEVA STEEL PRODUCTS (SHIP BREAKERS) LLP / JAI JAGDISH SHIP BREAKERS PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 150,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 110m, Draft: Any depth URL: http://www.sachdevagroup.in/ Open the SOC*2 |

| 27 |  |

Facility name: SAI METALTECH LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 75,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 49m, Draft: Any depth Open the SOC*2 |

| 28 |  |

Facility name: SALASAR BALAJI SHIP BREAKERS PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 60,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 45m, Draft: Any depth Open the SOC*2 |

| 29 |  |

Facility name: VMS INDUSTRIES LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 70,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 60m, Draft: Any depth Open the SOC*2 |

| 30 |  |

Facility name: SAGARLAXMI SHIP BREAKERS Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 50,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 77m, Draft: Any depth Open the SOC*2 |

| 31 |  |

Facility name: DIAMOND INDUSTRIES (S.B.D.) Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 75,000LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 52m, Draft: Any depth Open the SOC*2 |

| 32 |  |

Facility name: ANUPAMA STEEL LIMITED Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 39,580LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 83m, Draft: Any depth Open the SOC*2 |

| 33 |  |

Facility name: ATAM MANOHAR SHIP BREAKERS PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 40,000LDT Dismantling method: Intertidal landing MMaximum capacity of ship to be recycled: Any length, Breadth: 32.22m, Draft: Any depth Open the SOC*2 |

| 34 |  |

Facility name: PHP SHIP BREAKING AND RECYCLING INDUSTRIES LIMITED Location: Bangladesh (Chattogram) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing MMaximum capacity of ship to be recycled: Any length, Breadth: 100.00m, Draft: Any depth Open the SOC*2 |

| 35 |  |

Facility name: LEELA SUSTAINABLE SHIP RECYCLING PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 60,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: :40.00m, Draft: Any depth Open the SOC*2 |

| 36 |  |

Facility name: BMS SHIP RECYCLING Location: Türkiye (Izmir) Estimated annual recycling capacity (LDT*1):60,000LDT Dismantling method: landing method Maximum capacity of ship to be recycled: Length: Any length, Breadth: 68 m, Draft: Any depth Open the SOC*2 |

| 37 |  |

Facility name: PRIYABLUE RECYCLING LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 70,000 LDT Dismantling method: Intertidal landing MMaximum capacity of ship to be recycled: Any length, Breadth: :65m, Draft: Any depth URL: www.priyablue.com Open the SOC*2 |

| 38 |  |

Facility name: GURU ASHISH SHIP BREAKERS Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 40,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: :41m, Draft: Any depth Open the SOC*2 |

| 39 |  |

Facility name: SAI BANDHAN INFINNIUM PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 150,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 63m, Draft: Any depth Open the SOC*2 |

| 40 |  |

Facility name: KHUSHBOO INDIA PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 40,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: :59.50m, Draft: Any depth Open the SOC*2 |

| 41 |  |

Facility name: MAHAVIR SHIP BREAKERS Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 35,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: :69.7m, Draft: Any depth Open the SOC*2 |

| 42 |  |

Facility name: AGRASEN SHIP BREAKERS PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 30,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: :32.0m, Draft: Any depth Open the SOC*2 |

| 43 |  |

Facility name: RUDRA GREEN SHIP RECYCLING PRIVATE LIMITED Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 55.0m, Draft: Any depth Open the SOC*2 |

| 44 |  |

Facility name: BHARAT GREEN SHIP RECYCLERS LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 49,286 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 61m, Draft: Any depth URL: https://bharatgreenshiprecyclers.com/ Open the SOC*2 |

| 45 |  |

Facility name: HARIYANA SHIP BREAKERS LTD Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 50,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 93m, Draft: Any depth Open the SOC*2 |

| 46 |  |

Facility name: SHRI GAUTAM SHIP BREAKING INDUSTRIES PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 50,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 77m, Draft: Any depth Open the SOC*2 |

| 47 |  |

Facility name: HARIYANA SHIP DEMOLITION PRIVATE LIMITED Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 120m, Draft: Any depth Open the SOC*2 |

| 48 |  |

Facility name: NAVYUG SHIP BREAKING COMPANY Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 61m, Draft: Any depth Open the SOC*2 |

| 49 |  |

Facility name: GHAZIABAD SHIP BREAKERS PRIVATE LIMITED Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 40,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 45m, Draft: Any depth Open the SOC*2 |

| 50 |  |

Facility name: VIREDRA SHIP RECYCLERS LLP. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 50,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 40m, Draft: Any depth Open the SOC*2 |

| 51 |  |

Facility name: HONEY SHIP BREAKING PRIVATE LIMITED Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 50,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 60m, Draft: Any depth Open the SOC*2 |

| 52 |  |

Facility name: VIJAYKUMAR & CO. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 50,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 46m, Draft: Any depth Open the SOC*2 |

| 53 |  |

Facility name: SHIV CORPORATION Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 55,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 60m, Draft: Any depth Open the SOC*2 |

| 54 |  |

Facility name: M/S. S.N. CORPORATION (UNIT-02) Location: Bangladesh (Chattogram) Estimated annual recycling capacity (LDT*1): 150,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: Any Breadth, Draft: Any depth, Open the SOC*2 |

| 55 |  |

Facility name: KABIR STEEL LIMITED Location: Bangladesh (Chattogram) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth:85m, Draft: Any depth Open the SOC*2 |

| 56 |  |

Facility name: GOHILWAD SHIP BREAKING LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 40,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 45m, Draft: Any depth Open the SOC*2 |

| 57 |  |

Facility name: SHITAL ISPAT PVT. LTD. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 48m, Draft: Any depth Open the SOC*2 |

| 58 |  |

Facility name: SHREE SAI BABA SHIP BREAKING COMPANY Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 60,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 80m, Draft: Any depth Open the SOC*2 |

| 59 |  |

Facility name: KR SHIP RECYCLING YARD Location: Bangladesh (Chittagong) Estimated annual recycling capacity (LDT*1): 120,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: Any Breadth, Draft: Any depth URL: www.krshiprecycling.com Open the SOC*2 |

| 60 |  |

Facility name: SHIRDI STEEL TRADERS / SHANTI SHIP BREAKERS PRIVATE LIMITED Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 45m, Draft: Any depth URL: https://www.rkb.group/ Open the SOC*2 |

| 61 |  |

Facility name: MAHAVIR INDUCTOMELT PVT. LTD Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 110m, Draft: Any depth Open the SoC*2*2 |

| 62 |  |

Facility name: BHIKKAMAL CHHOTELAL EXIM PVT LTD Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 100,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 74m, Draft: Any depth Open the SoC*2*2 |

| 63 |  |

Facility name: RAI METAL WORKS PVT. LTD Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 75,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 40m, Draft: Any depth Open the SoC*2*2 |

| 64 |  |

Facility name: KAMDAR & ASSOCIATES Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 60,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 78m, Draft: Any depth Open the SoC*2*2 |

| 65 |  |

Facility name: KPG Enterprise Recyclers LLP Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 30,000 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 45m, Draft: Any depth Open the SOC*2*2 |

| 66 |  |

Facility name: Puneet Industries Pvt. Ltd. and M.K Shipping and Allied Industries Pvt. Ltd. Location: India (Gujarat) Estimated annual recycling capacity (LDT*1): 35,455 LDT Dismantling method: Intertidal landing Maximum capacity of ship to be recycled: Any length, Breadth: 112m, Draft: Any depth Open the SOC*2*2 |

Information in this table is based on the SRFP developed by the ship recycling facilities.

*1: LDT: Light Displacement Tonnage

*2: The image shown here is not a true copy of the certificate. However, the content is identical.

ClassNK published “Guidelines for Ship Recycling Facilities” in order to clarify the procedure and requirements for issuance of the SOC. The Guidelines can be download from “ClassNK MyPage” after the registration as a user.

ClassNK MyPage Login

For more information, please contact us to the following.

Green Certification Department

Tel: +81-3-5226-3025Fax: +81-3-5226-3026

E-mail: ihm@classnk.or.jp(for Inventory)

E-mail: recycling@classnk.or.jp (for Ship recycling facility)

E-mail: srpt@classnk.or.jp (for PrimeShip-GREEN/SRM)